Home › Forums › Computers, Games and Technology › Tech Specs of Plasma Cutters

This topic contains 7 replies, has 3 voices, and was last updated by ![]() Anonymous 3 years, 1 month ago.

Anonymous 3 years, 1 month ago.

- AuthorPosts

I’ve turned the internet upside down but can’t get a solid answer, can anyone explain these terms for me?

Quick background, I sell a few basic plasma cutters at work, now we’re getting more advanced ones. I understand how the process works but I don’t have any information on these arc initiation types:

Touch start – ok I’ve got this one: press torch down and release to start.

HF touch start –

HF non-touch start –

Pilot arc –The remaining 3 I’m stuck on, can anyone fill in the blanks here?

Thanks!

If they didn't have pussies they'd have targets on their backs,

Anonymous42HF, High frequency? Just guessing, I have an old hypertherm 20a for sheet metal.

P.S. Yup it’s high frequency: http://weldingweb.com/showthread.php?25405-Plasma-Cutter-Start-Functions

Anonymous0HF touch start – High frequency start which ionizes the gas between the electrode and the workpiece which ignites the main arc.

HF non-touch start – Contact touch start, scribing the wolfram electrode like a match on the workpiece, this causes a shortcut. taking off the electrode ignites the main arc.

Pilot arc – Creates ionized gas path for the main arc

Thanks Hollowmile. What I don’t understand is how can there be a HF contact start? I thought the point of HF was to avoid touching workpiece?

If they didn't have pussies they'd have targets on their backs,

Anonymous0thought the point of HF was to avoid touching workpiece?

Yes, right, that is why it is called HF touch start. The HF just “touches”, not the electrode the workpiece. There must be a distance between the electrode and the workpeace so that the HF can ionize the gas in between. Maybe the word “touch” is a bit perplexing.

The HF non touch start also called Contact touch, really needs a “mechanical touch” between the electrode and the workpiece. There is no HF. In this phrase maybe the shortcut “HF” is a bit perplexing.

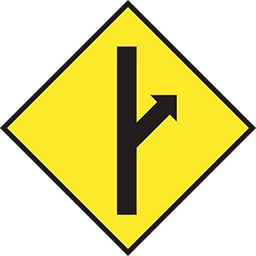

For the HF touch start, this may helps.

Anonymous42Great Diagram Hollowmile! I never really looked into the mechanics of it. I learned the more important things like heat and air pressure setting to preserve as much of the platinum in the electrode as long a I could.

Money matters really get my attention! PLATINUM!

Hollowmile, winner winner chicken dinner, I’ve added this to my list of cheat-sheets that will help me to sell the machines. Thanks again!

If they didn't have pussies they'd have targets on their backs,

Anonymous0Very Good – and welcome onboard.

Btw. your avatar, the Orange Amp cool. One of the original from Mat Matthias (Matamp)?

In the 80s nearly forgotten and a few years out of order.

A long time ago, 20 years or so, I repared Tube Amps and built some by myself according to the circuit diagrams of Jim Marshall. A friend once gave me a Groove Tube Handbook with several circuit diagrams of Marshall and Leo Fender tube amps.- AuthorPosts

You must be logged in to reply to this topic.

921526

921524

919244

916783

915526

915524

915354

915129

914037

909862

908811

908810

908500

908465

908464

908300

907963

907895

907477

902002

901301

901106

901105

901104

901024

901017

900393

900392

900391

900390

899038

898980

896844

896798

896797

895983

895850

895848

893740

893036

891671

891670

891336

891017

890865

889894

889741

889058

888157

887960

887768

886321

886306

885519

884948

883951

881340

881339

880491

878671

878351

877678